I-activated carbon (AC) ibhekisa kwizinto ezine-carbonaceous ephezulu ezine-porosity ephezulu kunye nokukwazi ukufunxa eziveliswa ngomthi, amaqokobhe ekhokhonathi, amalahle, kunye neekhowuni, njl.njl. I-AC yenye yezinto ezisetyenziswa rhoqo kwiimveliso ezahlukeneyo ukususa ungcoliseko oluninzi emanzini nasemoyeni. Ekubeni i-AC yenziwe kwimveliso yezolimo kunye nenkunkuma, ibonakalise ukuba yindlela elungileyo kunemithombo engasetyenziswa ngokutsha nebiza kakhulu. Ukulungiselela i-AC, kusetyenziswa iinkqubo ezimbini ezisisiseko, i-carbonization kunye nokusebenza. Kwinkqubo yokuqala, izinto ezisandula ukwenziwa zifakwa kumaqondo obushushu aphezulu, phakathi kwama-400 nama-850°C, ukuze kukhutshwe zonke izinto eziguquguqukayo. Ubushushu obuphezulu obuphezulu bususa zonke izinto ezingezizo iikhabhoni kwi-precursor ezifana ne-hydrogen, i-oxygen, kunye ne-nitrogen ngendlela yeegesi kunye nee-tars. Le nkqubo ivelisa i-char enomxholo wekhabhoni ephezulu kodwa indawo ephantsi kunye nokufunxa. Nangona kunjalo, inyathelo lesibini libandakanya ukusebenza kwe-char eyenziwe ngaphambili. Ukwandiswa kobukhulu be-pore ngexesha lenkqubo yokuvula kungahlulwahlulwa kathathu: ukuvulwa kwe-pore ezazingafikeleleki ngaphambili, uphuhliso lwe-pore entsha ngokuvuselela okukhethiweyo, kunye nokwandiswa kwe-pore ezikhoyo.

Ngokwesiqhelo, iindlela ezimbini, ezomzimba nezekhemikhali, zisetyenziswa ukuze kusebenze ukuze kufunyanwe indawo yomphezulu oyifunayo kunye ne-porosity. Ukusebenza ngokomzimba kubandakanya ukusebenza kwe-carbonized char kusetyenziswa iigesi ze-oxidizing ezifana nomoya, i-carbon dioxide, kunye nomphunga kumaqondo obushushu aphezulu (phakathi kwama-650 nama-900°C). I-carbon dioxide idla ngokuthandwa ngenxa yendalo yayo ecocekileyo, ukuphathwa okulula, kunye nenkqubo yokusebenza elawulekayo malunga nama-800°C. Ukulingana kwe-pore ephezulu kunokufumaneka ngokusebenzisa i-carbon dioxide xa kuthelekiswa nomphunga. Nangona kunjalo, ekusebenzeni ngokomzimba, umphunga uthandwa kakhulu xa kuthelekiswa ne-carbon dioxide kuba i-AC enommandla ophezulu womphezulu inokuveliswa. Ngenxa yobukhulu obuncinci bamanzi bemolekyuli, ukusasazeka kwayo ngaphakathi kwesakhiwo se-char kwenzeka ngokufanelekileyo. Ukusebenza ngumphunga kufunyenwe kuphindwe kabini ukuya kathathu kune-carbon dioxide enezinga elifanayo lokuguqulwa.

Nangona kunjalo, indlela yokwenza iikhemikhali ibandakanya ukuxuba i-precursor kunye nee-activating agents (NaOH, KOH, kunye neFeCl3, njl.njl.). Ezi arhente zisebenzayo zisebenza njengee-oxidants kunye nee-dehydrating agents. Kule ndlela, i-carbonization kunye ne-activation zenziwa ngaxeshanye kubushushu obuphantsi obuyi-300-500°C xa kuthelekiswa nendlela yokusebenza. Ngenxa yoko, ichaphazela ukubola kwe-pyrolytic kwaye, emva koko, ikhokelela ekwandeni kwesakhiwo esiphucukileyo se-porous kunye ne-carbon dievement ephezulu. Iingenelo eziphambili zendlela yokwenza iikhemikhali ngaphezu kwe-physical yimfuno yobushushu obuphantsi, izakhiwo eziphezulu ze-microporosity, indawo enkulu yomphezulu, kunye nexesha elincinci lokugqiba impendulo.

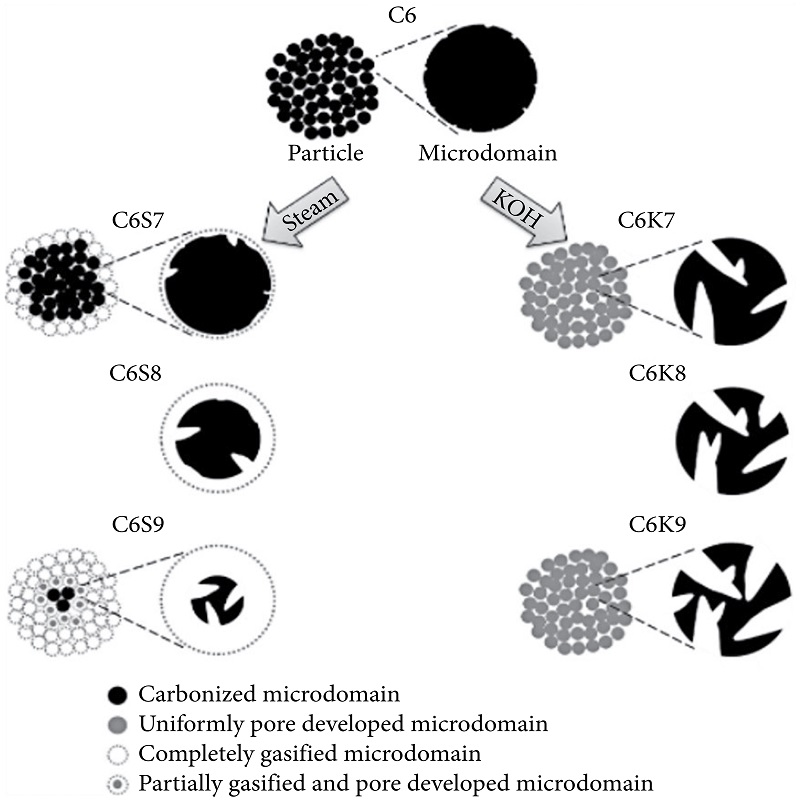

Ukuphakama kwendlela yokwenza i-chemical activation kungachazwa ngokusekelwe kwimodeli ecetywayo nguKim kunye nabantu asebenza nabo [1] apho kufumaneka khona ii-microdomains ezahlukeneyo ezijikelezayo ezinoxanduva lokwenziwa kwee-micropores kwi-AC. Kwelinye icala, ii-mesopores ziphuhliswa kwiindawo eziphakathi kwee-microdomain. Ngovavanyo, zenze i-activated carbon evela kwi-phenol-based resin yi-chemical (esebenzisa i-KOH) kunye ne-physical (esebenzisa i-steam) activation (Umfanekiso 1). Iziphumo zibonise ukuba i-AC eyenziwe yi-KOH activation yayinendawo ephezulu ye-2878 m2/g xa kuthelekiswa ne-2213 m2/g ngokusebenza kwe-steam. Ukongeza, ezinye izinto ezifana nobukhulu bee-pore, indawo yomphezulu, umthamo wee-micropore, kunye nobubanzi bee-pore obuqhelekileyo zonke zifunyenwe zingcono kwiimeko ezisebenza kwi-KOH xa kuthelekiswa ne-steam activated.

Umahluko phakathi kwe-AC Ilungiselelwe kwi-activation yomphunga (C6S9) kunye ne-activation ye-KOH (C6K9), ngokwahlukeneyo, ichazwe ngokwemodeli yesakhiwo se-microstructure.

Ngokuxhomekeke kubukhulu besuntswana kunye nendlela yokulungiselela, ingahlulwahlulwa ibe ziintlobo ezintathu: i-AC enikwe amandla, i-AC eneengqukuva, kunye ne-AC enezingqimba. I-AC enikwe amandla yenziwe ngee-granules ezincinci ezinobukhulu obuyi-1 mm kunye nobubanzi obuphakathi obuyi-0.15-0.25 mm. I-AC enezingqimba inobukhulu obukhulu kunye nommandla ongaphandle ongaphantsi. I-AC enezingqimba isetyenziselwa ukusetyenziswa kwezigaba ezahlukeneyo zolwelo kunye nezigaba zegesi ngokuxhomekeke kumlinganiselo wazo wobukhulu. Udidi lwesithathu: i-AC enezingqimba idla ngokwenziwa kwi-petroleum pitch enobubanzi obuphakathi kwe-0.35 ukuya kwi-0.8 mm. Yaziwa ngamandla ayo aphezulu oomatshini kunye nomxholo ophantsi wothuli. Isetyenziswa kakhulu kwiindawo zokusetyenziswa kwebhedi ezimanzi ezifana nokuhluza amanzi ngenxa yesakhiwo sayo esingqukuva.

Ixesha lokuthumela: Juni-18-2022