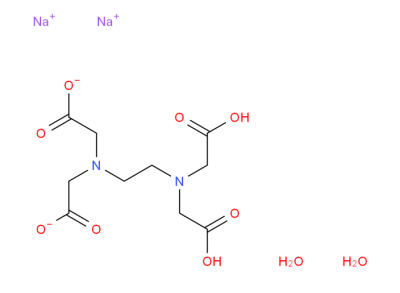

I-Ethylene Diamine Tetraacetic Acid Disodium (EDTA Na2)

Iinkcukacha:

| Into | Umgangatho |

| Inkangeleko | Umgubo oMhlophe |

| Uvavanyo (C)10H14N2O8Na2.2H2O) | ≥99.0% |

| IPlumbum(Pb) | ≤0.0005% |

| I-Ferrum (Fe) | ≤0.001% |

| I-Chloride (Cl) | ≤0.05% |

| I-Sulfate (SO2)4) | ≤0.05% |

| PH(50g/L; 25℃) | 4.0-6.0 |

| Ubungakanani beParticle | <40mesh≥98.0% |

Isicelo:

I-EDTA 2NA sisixhobo esibalulekileyo sokudibanisa ii-ion zesinyithi kunye nokwahlula iintsimbi. Le mveliso isetyenziswa njengesisombululo sokulungisa i-bleaching kwimifanekiso yombala, ukuphuhlisa kunye nokucubungula izinto ezisebenzisa umbala, kunye nokongeza idayi, i-arhente yonyango lwefayibha, isongezo sezinto zokuhombisa, amayeza, ukutya, imveliso ye-microfertilizer yekhemikhali yezolimo, i-anticoagulant yegazi, i-arhente yokudibanisa, isepha, isiqinisi, irabha yokwenziwa, i-polymerization initiator kunye ne-arhente yohlalutyo lobuninzi besinyithi esinzima, njl. Kwinkqubo yokuqalisa ukuncipha kwe-chlorinated ye-SBR polymerization, i-disodium EDTA isetyenziswa njengenxalenye yesixhobo esisebenzayo, ikakhulu ekudibaniseni ii-ion zesinyithi kunye nokulawula izinga lokuphendula kwe-polymerization.

Inkqubo yeMveliso:

1. Yongeza kancinci umxube we-sodium cyanide kunye ne-formaldehyde kwisisombululo samanzi se-ethylenediamine ngomlinganiselo othile, uze udlulise umoya kwi-85℃ phantsi koxinzelelo oluphantsi ukuze ususe igesi ye-ammonia. Emva kwempendulo, lungisa ixabiso le-Ph libe yi-4.5 nge-sulfuric acid egxininisiweyo, uze emva koko utshintshe umbala, uhluze, ugxininise, udibanise kwaye wahlukanise, uze wome ukuze ufumane imveliso egqityiweyo.

2. Xuba i-100kg ye-chloroacetic acid, i-100kg yomkhenkce kunye ne-135kg yesisombululo se-30% se-NaOH, yongeza i-18kg ye-83% ~ 84% ye-ethylenediamine phantsi kokuyixuba, kwaye uyigcine kwi-15℃ kangangeyure eli-1. Yongeza kancinci isisombululo se-30% se-NaOH kwiibhetshi de i-reactant ibe yi-alkaline, kwaye uyigcine kubushushu begumbi iiyure ezili-12. Fudumeza ukuya kwi-90℃, yongeza i-activated carbon ukuze itshintshe umbala. I-filtrate ilungiswa kwi-4.5 Ph kunye ne-hydrochloric acid kwaye igxininiswe kwaye ihluzwe kwi-90℃; i-filtrate iyapholiswa, i-crystallized, yahlulwe kwaye ihlanjwe, kwaye yomiswe kwi-70℃ ukuze ufumane imveliso egqityiweyo.

3. Yenziwe ngesenzo se-ethylenediaminetetraacetic acid kunye nesisombululo se-sodium hydroxide: Kwiflaski ye-reaction ye-2L exhotyiswe nge-stirrer, yongeza i-292g ye-ethylenediaminetetraacetic acid kunye ne-1.2L yamanzi. Yongeza i-200mL yesisombululo se-30% ye-sodium hydroxide phantsi kokuxubha kwaye ufudumale de yonke i-reaction igqitywe. Yongeza i-20% ye-hydrochloric acid kwaye unciphise i-pH = 4.5, ufudumale ukuya kwi-90℃ kwaye ugxile, uhluze. I-filtrate iyapholiswa kwaye iikristale ziyavuthuluka. Khipha kwaye wahlukanise, uhlambe ngamanzi acocekileyo, womise kwi-70℃, kwaye ufumane imveliso ye-EDTA 2NA.

4. Yongeza i-ethylenediaminetetraacetic acid kunye namanzi kwi-enameled reaction tank, yongeza isisombululo se-sodium hydroxide phantsi kokuxubha, fudumeza de yonke i-reaction ifikelele, yongeza i-hydrochloric acid kwi-pH 4.5, fudumeza ukuya kwi-90°C uze ugxile, uhluze, i-filtrate iphole, hluza iikristale, uhlambe ngamanzi, womise kwi-70°C, uze ufumane i-EDTA 2NA.